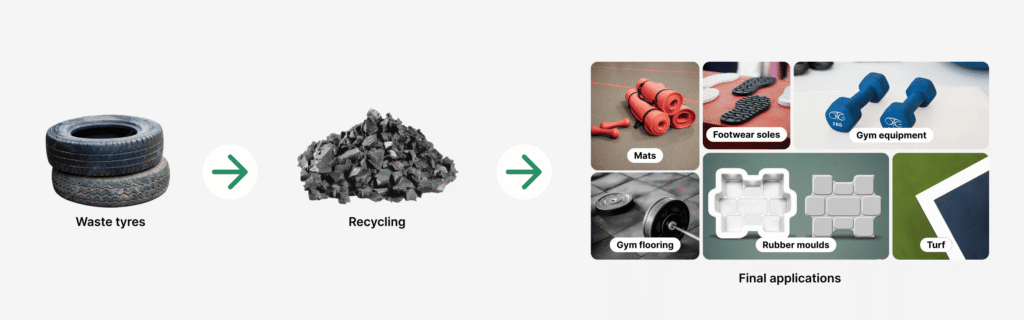

Transforming Scrap Tyres into Sustainable Value

Premium, steel‑&‑fibre‑free materials—delivered on time, at competitive rates

-

Crumb Rubber

Steel and fibre-free granules, ideal for sports surfaces, moulded goods, and rubberized asphalt.

-

Steel Wire

Recycled tyre-wire for industrial applications-sorted, cleaned, and ready for reuse.

Bead Wire

High-tensile steel extracted from tyre beads, suitable for reinforcement and manufacturing needs.

Tyre Shreds

Ideal for granulation and chip making, delivering efficient production of crumb rubber and tyre chips.

Rubber Chips

Perfect for filtration, playgrounds, or granulation, yielding TPO grade granules and alternative cement fuel.

Rubber Granules

Fine-grade granules with tight size tolerances, engineered for precision in high-performance materials.

Our Story

From Waste to Worth

In 2019, we set out to give scrap tyres a second life & reduce the environmental burden they cause. Today, we repurpose end‑of‑life tyres into eco‑friendly materials, and this is just a beginning.

How It Works

Precision Recycling

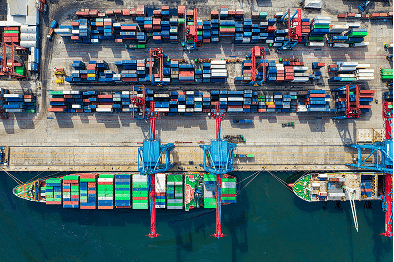

Collection, Import & Procurement

We partner with tyre dealers, service centres, international importers and municipal waste facilities to secure end‑of‑life truck and bus tyres.

1

Unloading & Initial Inspection

Tyres are offloaded onto conveyor belts and undergo a visual check for non‑tyre debris (stones, metal fasteners) that could affect the quality.

2

Sidewall & Tread Separation

Automated knives split the tyre’s sidewalls from the central tread, allowing dedicated downstream processes for each component.

3

Bead‑Wire Removal

Specialised bead‑wire remover machines extract the high‑tensile steel bead wire, preserving its integrity for re‑melting.

4

Primary Shredding (Rubber Blocks)

The remaining carcass is fed into a low‑speed, high‑torque primary shredder, breaking tyres into 20–300 mm rubber blocks.

5

Secondary Shredding (Rasper)

Rubber blocks are further reduced by a shredder, yielding 5–25 mm chips that balance throughput with separation efficiency.

6

Steel Extraction

Chips pass under powerful magnetic separators, which remove 100% of embedded steel wires for recycling into construction‑grade rebar.

7

Granulation

Metal‑free rubber chips enter granulators, where it grinds them into 1–5 mm granules per client specification.

8

Fibre Separation

Granules are conveyed through air‑classifier systems that blow out textile fibres, resulting in pure rubber crumb. This step guarantees 100% fibre‑free output

9

Sieve Classification

Crumb is sieved through multi‑deck screens to segregate particles into defined mesh sizes (10‑ to 40‑mesh).

10

Fine Grinding

Under controlled conditions, select fractions undergo fine milling to produce fine mesh up to 140 mesh.

11

Final Sieving & Quality Control

We re‑sieve all output to verify particle uniformity and conduct lab tests (moisture, ash content). Batches must meet ISO 9001 purity standards.

12

Packaging & Dispatch

Approved rubber crumbs and by‑products are packed in 50 kg high‑strength PP bags or bulk jumbo bags ready to dispatch.

13

Why Green Global Technologies?

Unwavering Quality & Consistency

Batch‑tested to meet or exceed industry standards—every shipment performs exactly as promised.

On‑Time, Global Delivery

Proven logistics network ensures your materials arrive when and where you need them.

Competitive, Transparent Pricing

Clear rate cards and bulk‑order discounts guarantee the best value—no hidden fees.

Custom Sizing & Packaging

From fine granules to large blocks, and plain or printed bags, we tailor every detail to your requirements.

Cutting‑Edge In‑House Tech (Coming Soon)

Soon to launch proprietary recycling machines that boost yield and further reduce carbon footprints.

Commitment to Zero Carbon Footprint

Active R&D investments drive us toward carbon‑neutral operations—and you benefit from our green credentials.

Mr. Jitendra Patel

Founder, CEO

Leadership Guided by ‘Patthar Se Pani Nikalna’

Mr. Jitendra Patel founded Green Global Technologies in 2019 with a vision to turn end‑of‑life tyres into valuable, sustainable resources. When the pandemic threatened early operations, he embraced his guiding principle—“patthar se pani nikalna”—finding solutions in the toughest of times by investing in technology and forging strong industry partnerships.

Find Our Tyre Recycling Hub

Partners & Clients

Latest Updates

- February 24, 2025

This is a new blog title

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

- February 24, 2025

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

- February 24, 2025

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

- February 24, 2025

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

- February 5, 2025

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

FAQ’s

Quick Answers to Top Queries

Which type of raw material is procured?

We source bus and truck radial (TBR) tyres exclusively, ensuring a uniform feedstock.

What type of packaging bag is used?

Standard high‑strength PP bags (plain) at 50 kg each—custom prints and sizes available on request.

Can you customize package weight or size?

Absolutely—we tailor both product sizing and bag weights to your exact specifications.

What are your typical delivery timelines?

Domestic orders ship within 7–10 business days; international lead times vary by destination.

Is crumb rubber produced 100% steel and fibre free?

Yes—our multi‑stage magnetic and air separators guarantee zero metal or fibre contamination.

Have more questions?

Ready to get started? Fill out the form below, and our team will be in touch within one business day to discuss your custom tyre‑recycling needs and provide a tailored quote.

Want to visite our office?

Quick links

©2019 Green Global Technologies. All rights reserved.